|

*Cette page est à disposition uniquement dans la langue anglaise.

V-Tech develops and manufactures food processing and packaging machines, transport systems and other supporting equipment for the food industry. In addition, we are of service in the field of process installations for low- to high viscous foods and healthcare products.

The V-Tech Line products are produced in-house in the Netherlands and we also work together with renowned partners to complement our portfolio. Execution mostly on customer specification. Together with you, we try to convert your recipes to process systems especially tailored to you. If needed, supported by testing in a pilot environment.

Applications

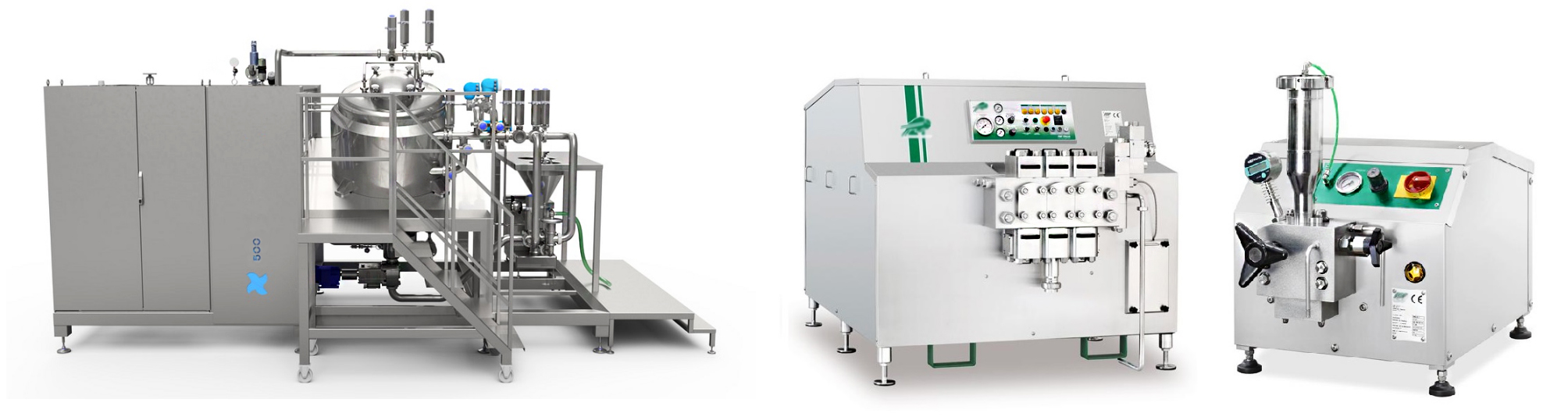

• Dissolve, disperse and emulsify

• Dosing and filling

• Wash

• Heat transfer and evaporation

• Aseptic and non-aseptic processing

• Cleaning In Place (CIP) and Sterilization In Place (SIP)

• Pumping and homogenizing

Cutters

.jpg)

Testing

In collaboration with our partner, we offer the possibility to carry out product testing. Intended to demonstrate the benefits of the equipment and to provide support in product development. This can also take place at your location if desired.

Possibilities

• Dosing or filling/weighing

• Processes available for testing:

• Emulsify inline and batch

• Cooking and cooling in the kettle

• Vacuum cooking - cooling - concentrate

• CIP

Additional operations can be arranged with our partners.

Processes & Product Examples

Ranging from:

General:

Hygienic, easy-to-clean equipment for cutting, (gently) mixing, pumping, dissolving or controlled heat transfer is important in all these products.

These systems can be custom-made and equipped with different mixing technologies, vacuum control and heating & cooling options. The user-friendly operator interface includes recipe storage and data logging.

Deployable in HACCP, GMP+, BRC, IFS and ISO environments. Food Safety -> Sanitary/Hygienic Design and Construction, Stainless Steel 304/316, FDA approved plastics.

In addition, in our portfolio: