|

*Cette page est à disposition uniquement dans la langue anglaise.

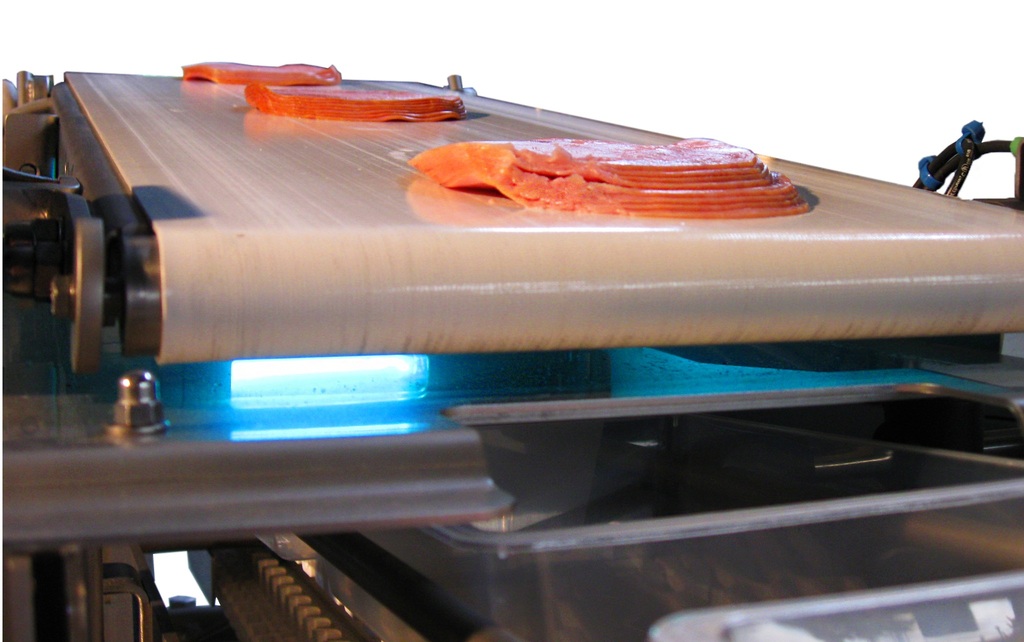

Contamination through contact with surfaces is one of the most common causes of the contamination of foodstuffs with bacteria and fungi. In general, the conveyor belts for different kinds of fresh food (meat, cheese, etc) are responsible for this. These conveyor belts, among other, are therefore important places where cross-contamination can occur. As the day passes, the number of bacteria on the belt can drastically increase.

To keep the germ numbers within acceptable values, an interim cleaning with water and chemicals should be scheduled. A major disadvantage, however, is the capacity loss and the already incurred loss of quality.

For the benefit of the process efficiency and quality of the product, the solution is to equip the product loader with an integrated UV-C light unit.

With UV-C radiation at this position in the process, V-Tech Line offers an effective remedy without the use of water, chemicals and loss of production. It reduces the risk of accumulation of microorganisms by the disinfection of the surface (belt surface or packaging) and prevents infections and the spread of micro- organisms. These units can also installed in your existing process installations and conveyorsystems.

remedy without the use of water, chemicals and loss of production. It reduces the risk of accumulation of microorganisms by the disinfection of the surface (belt surface or packaging) and prevents infections and the spread of micro- organisms. These units can also installed in your existing process installations and conveyorsystems.

New!!

The UV-C disinfection lamps can now also be integrated in all product loaders of the V-Tech Line packing machines.

Disinfection of your conveyor on the final point of packing! Reduction of bacteria count, reducing the risk of contamination and thus extending the shelf life of your fresh products!

Additional:

Various products, raw materials and semi-finished products can be disinfected during the packaging process. In this way, yeasts and fungus on the surface are effectively eliminated before packing or cutting up in slices or cubes.

Contamination of the fresh cutting edges by the slicer is avoided. The product remains in a hygienic impeccable State and shelf life is arguably better. Application of this technology during the stage of packaging affects the UV-C light this even more.

Packaging lines and ' Clean Room ':

Not only conveyor belts s but also open packaging as tray' or cups can become infected, before being filled with product.

For these situations, the conveyor systems also run with UV-C light tunnels, where the packaging can be lightened. Also suitable for disinfecting materials and products before entrance in ' clean room ' environments.

General benefits:

Hygienic environment and producing with clean air.

n processing sensitive products such as foodstuffs, a conditioned climate is of great importance. In the air hovering countless dangers as bacteria, viruses and fungi. These germs can severely damage your product and your reputation. Prevent contamination of your product with a sterile and pure air! We have equipment on the basis of UVC lighting and bipolar ionization which neutralize micro-organisms in the air. Both techniques remove also ethylene.

In conventional air treatment systems filters are used. They filter relative larger particles but are not effective against microorganisms. These bacteria, viruses and fungi are active and multiply rapidly. This microbiological contamination in the air however, can be avoided.

Simply by making use of modern techniques, that are simple to install and earn itself back! The air systems are easy to install and surprising cost effective. Built in air treatment systems and as individual units, sterile air can easily be created.

Inidivual units ionize the air and and prevent contamination. To be build into a air treatment cabinet or channel or as individual units to the ceiling.

UVC units will lighten the circulating air and kill living organisms therein. To be build into a air treatment cabinet or channel or as individual units to the ceiling.

In cooling rooms can evaporators be a source of air contamination. The cleaning of evaporators by UV-C lamps give less maintenance on the evaporators and provide cleaner air. We arrange advice for you how we can help you to improve the air quality. For example, consider installing a number of UVC lamps in your air treatment system, the continuous disinfection of your evaporators or ionizing the present environmental air.

Experie nce of air disinfection in:

nce of air disinfection in:

UV-C :

Enlighten with a UV lamp air or an evaporator and bacteria cannot multiply. This is because the UV-C (part of the light spectrum) can damage DNA, and damaged DNA prevents bacteria and fungi to multiply.

Bipolar ionization :

Ionize is adding energy (electricity) to the air. Oxygen molecules are split into two ions (positive and negative). These ions are unstable and bind themselves with living organisms, which will die.